| |

| 3D-Druck Technologie | Fused Filament Fabrication (FFF) |

| Auflösung | Minimale Schichtstärke ca. 0,05 mm, abhängig von Material und Düsengröße |

| Geschwindigkeit | bis 300 mm/s mit aktiver Resonanzdämpfung |

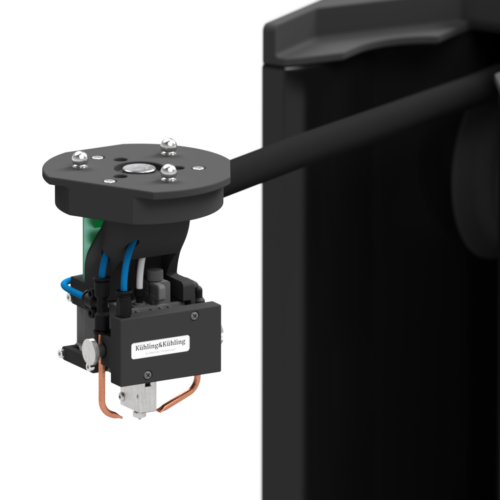

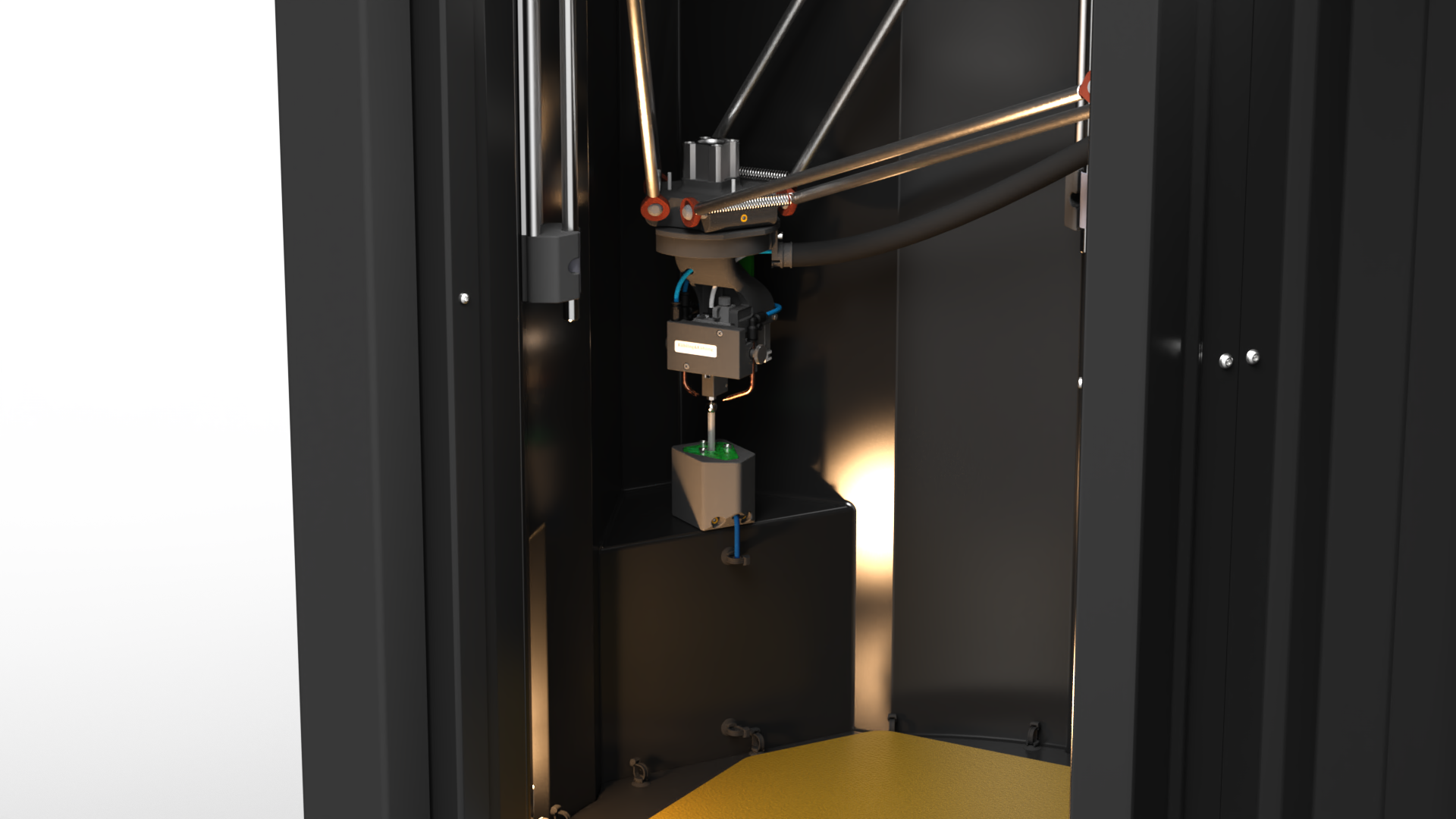

| Werkzeugwechsler | bis zu 4 unabhängige Werkzeuge (aktuell: Druckköpfe, Messtaster; Sonderentwicklungen möglich) |

| Filament | Ø1,75 mm, offenes System |

| Materialien | Kompatibel mit ungefüllten, verstärkten (GF/CF) und flexiblen FFF-Filamenten inkl. PLA, PETG, ABS, ASA, TPU, PC, PA, PEI, PEEK u.v.m. |

| Druckköpfe | Hochleistungs-Markenextruder von E3D (Hemera Direct Drive) in Hochtemperaturausführung bis 500 °C, Ø0,60 mm Düse vorinstalliert, stufenlos elektronisch geregelte Druckluft-Bauteilkühlung, bis zu 100 N Förderkraft (abhängig vom Filamentmaterial), integrierter Energiekettenrückzug mit kontrollierten Mindestradien für den Filamentpfad |

| Filamentzuführung | Entfeuchtende, staubgeschützte Materialaufbewahrung bis 3kg Spulengröße; aktive Filamentvorfördereinrichtung am Filamentspulenhalter |

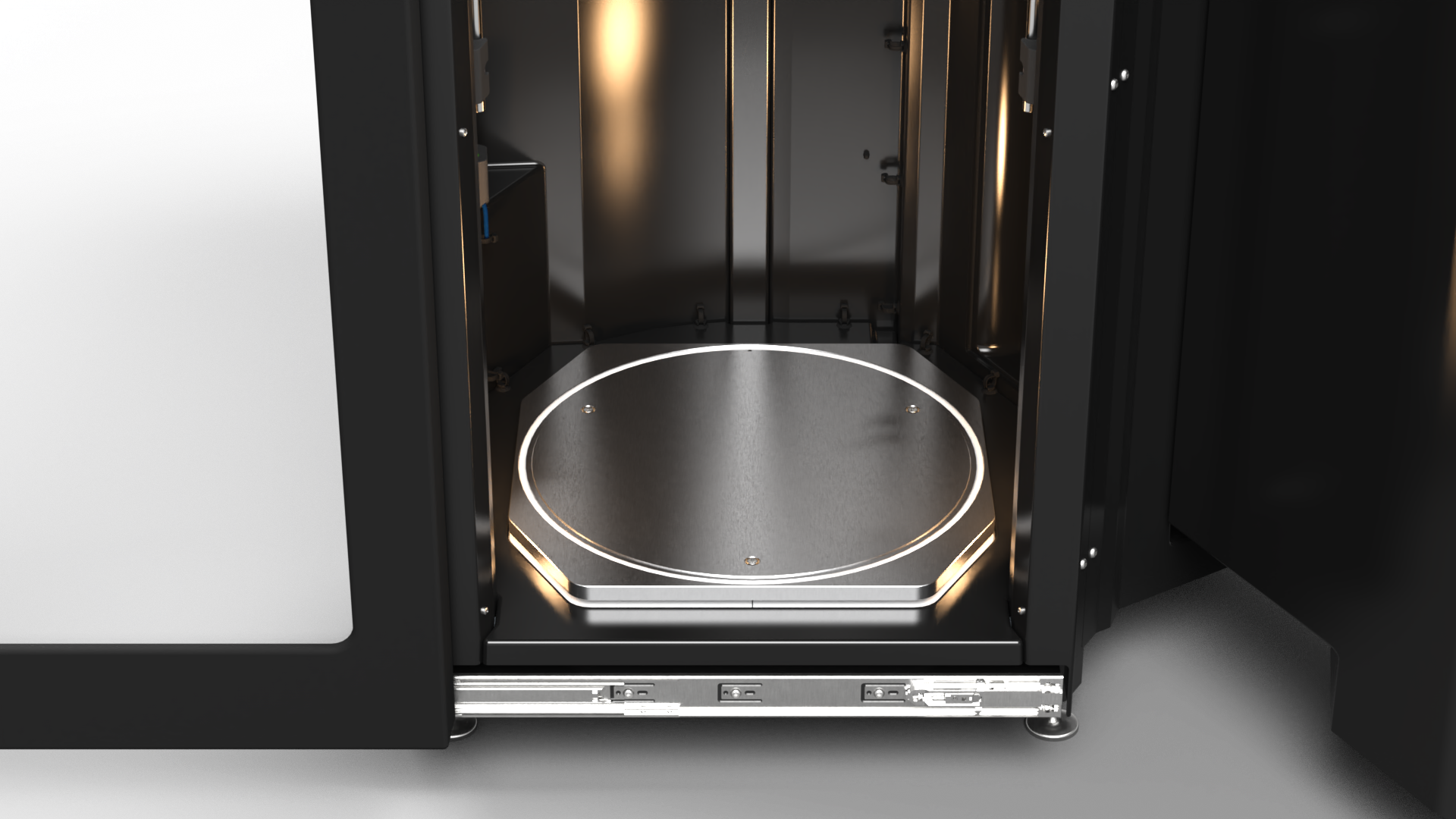

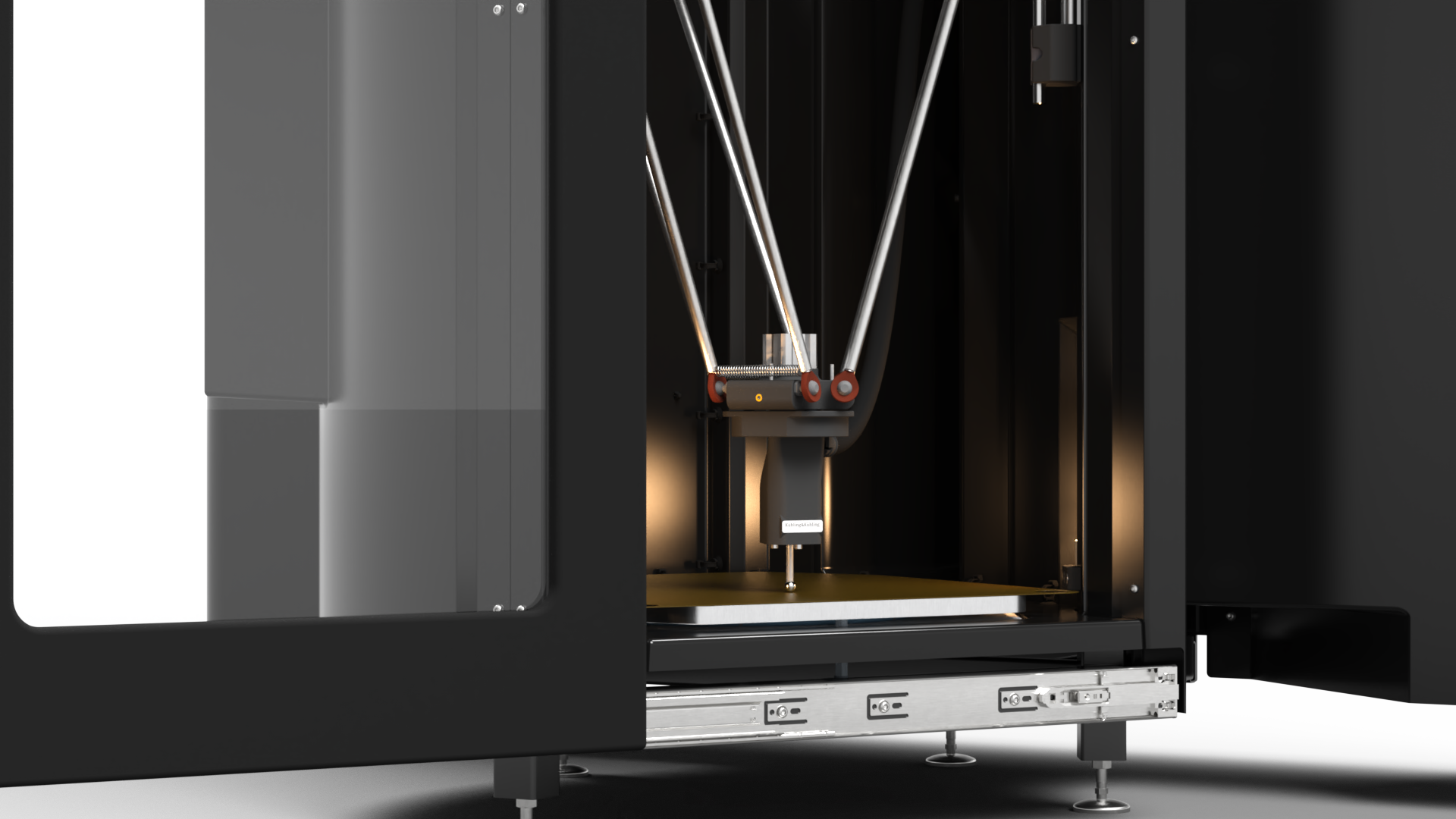

| Bauraum | Ø400×600 mm (75 Liter), aktiv beheizte Umluft bis 90 °C |

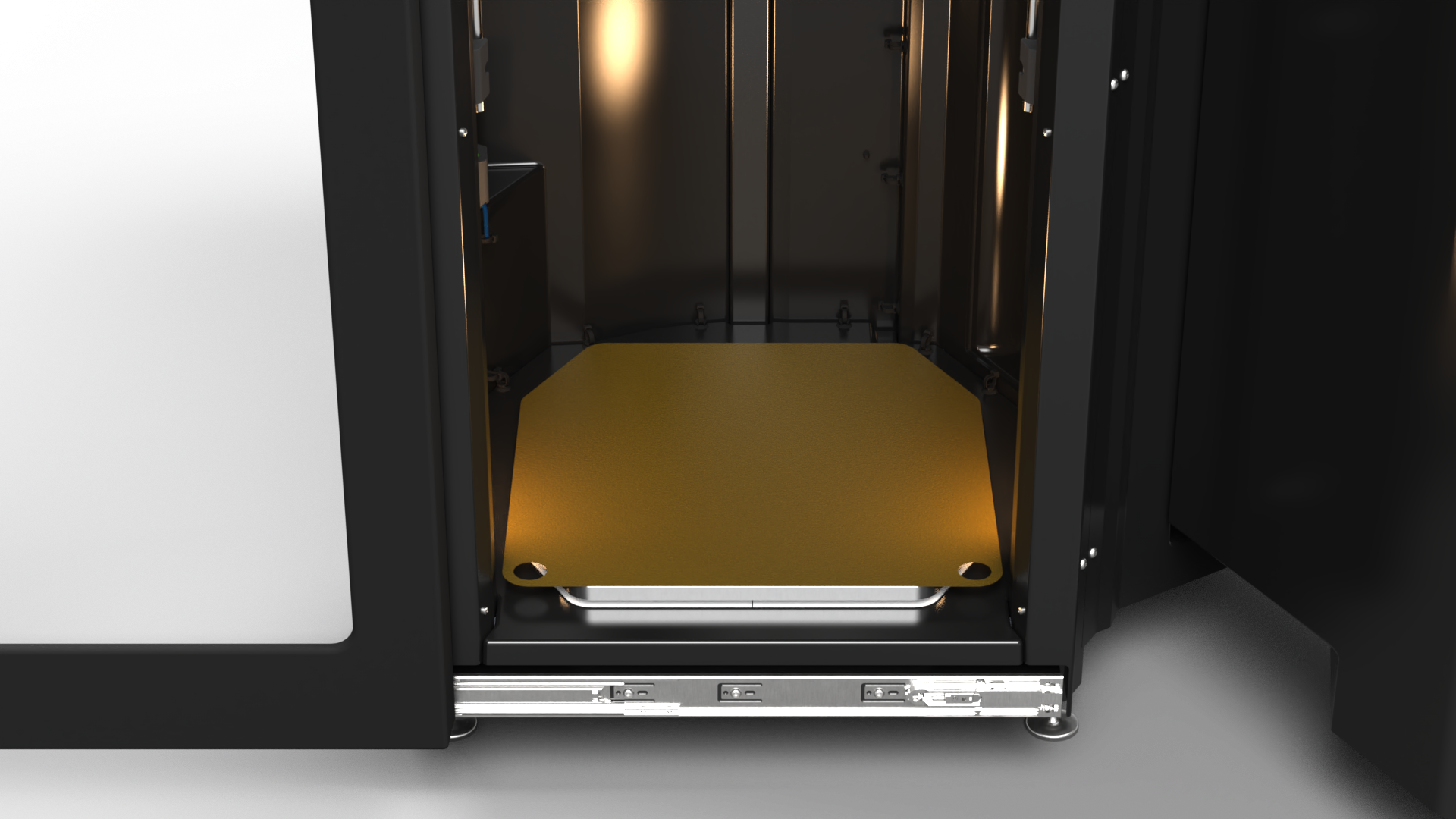

| Druckbett | Beheiztes Aluminium-Druckbett bis 180 °C mit Vakuumaufspannung für Folien/Platten als Drucksubstrat. PEI-beschichtete Stahlplatte im Lieferumfang enthalten. |

| Benutzerschnittstelle | Integrierter 22“ Touchscreen, 4-Kern-Steuercomputer mit vollem linuxbasierten Betriebssystem |

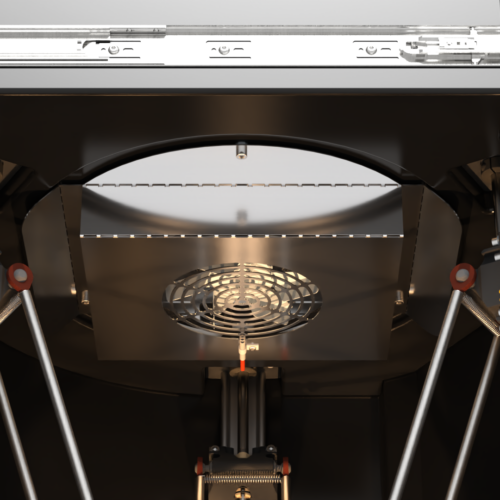

| Vollautomatische Kalibrierung | Messtaster-Werkzeug zur automatischen Druckbettkalibrierung und stationärer 3D-Taster zur Kalibrierung der Werkzeuge in Länge und X-/Y-Versatz |

| Digitale Prozessüberwachung | Filamentpräsenzsensor, Werkzeugpräsenz-/Werkzeugkollisionssensor, Druckluft- und Vakuumsensoren, Servo-Überlast-Alarm, Überhitzungssensoren, Türschalter |

| Elektronik | Modulare Steuerelektronik aus eigener Entwicklung mit standardisiertem Bus-System; ermöglicht individuelle Erweiterung um neue Funktionen und ergänzende Baugruppen sowie zu späterem Zeitpunkt angebotene Erweiterungsoptionen; auch für kundenspezifische Sonderentwicklungen steht Kühling&Kühling zur Verfügung |

| Antriebe | Closed-Loop-Servoantriebe, Linearführungen und Spindeltriebe wartungsfrei durch Hochleistungspolymergleitlager |

| Software | Open Source Slicing-Software (PrusaSlicer, verfügbar für Windows/MacOS/Linux) mit umfangreichen professionellen Konfigurations- und Analysefunktionen, offene G-Code Schnittstelle |

| Schnittstellen | Gigabit Ethernet; Wifi 2,4 GHz und 5.0 GHz IEEE 802.11b/g/n/ac; USB; Cloudspeicher-Anbindung (Dropbox, Nextcloud o.ä.) |

| Rahmen | Stahl |

| Gehäuse | GFK doppelwandig, verglaste Tür (PC) |

| Energieversorgung | 230V AC 16A, Druckluft 6-8bar |

| Abmessungen (inkl. Werkzeugwechsler) | Ca. 130x150x185cm (BxTxH); Liefermaße kompatibel mit DIN-Türmaßen ab 80cm lichter Türdurchgangsbreite |

| Service | 12 Monate Garantie inkl., über Serviceverträge erweiterbar |